Unlocking the Power of Engines: A Comprehensive Overview to Performance and Effectiveness

Recognizing the intricate mechanics of engines is essential for both performance enthusiasts and daily motorists. The responses may redefine our technique to engine efficiency and effectiveness in methods that are both informing and necessary.

Recognizing Engine Essentials

What constitutes the fundamental technicians of an engine? At its core, an engine is an equipment created to transform gas right into mechanical power via a collection of regulated surges or burning processes. The primary components consist of the cyndrical tube, piston, crankshaft, camshaft, and valves. The cylinder works as the chamber where burning takes place, while the piston relocates within the cylinder to convert the power from burning into linear activity (ford fiesta engine).

The crankshaft then transforms this straight movement right into rotational power, which ultimately powers the lorry. The camshaft regulates the opening and closing of the shutoffs, regulating the consumption of air and gas and the expulsion of exhaust gases. Furthermore, the engine relies on a very carefully calibrated fuel-air combination, ignition system, and cooling down system to guarantee optimal efficiency and performance.

Understanding engine essentials likewise entails acknowledging the significance of engine cycles, such as the four-stroke cycle, that includes intake, power, compression, and exhaust strokes. Each phase is important in ensuring the engine works smoothly and successfully. Proficiency of these fundamental technicians prepares for checking out more complicated engine characteristics and performance metrics, crucial for optimizing both power output and effectiveness.

Secret Efficiency Metrics

Secret performance metrics are necessary for examining an engine's performance and power output, giving important insights for both producers and customers. These metrics work as benchmarks for engine efficiency, permitting informed decisions in style, production, and purchasing.

One of the main metrics is horse power, which evaluates the engine's capacity to execute work over time. Torque, determined in pound-feet, is another vital metric that suggests the engine's rotational pressure, directly impacting acceleration and pulling capacity. Fuel performance, usually determined in miles per gallon (MPG) or liters per 100 kilometers (L/100km), examines just how efficiently the engine transforms fuel right into activity, impacting environmental factors to consider and functional prices.

Additionally, thermal effectiveness procedures just how well an engine transforms fuel energy right into beneficial job, exposing insights right into power losses mainly through warmth. Exhaust levels, including carbon dioxide and NOx, are likewise vital, showing the engine's environmental influence and compliance with regulatory criteria.

Tuning Techniques for Efficiency

Tuning methods play a considerable duty in boosting engine efficiency by optimizing performance metrics determined in earlier discussions (ford fiesta engine). Different techniques exist to adjust an engine, each adding to boosted gas economy and decreased emissions

One effective technique is adjusting the air-fuel ratio, guaranteeing the engine operates within the optimal combustion regime. A leaner mixture can enhance gas performance, yet it has to be stabilized to avoid misfires or engine knock. In addition, reprogramming the engine monitoring system can rectify criteria such as ignition timing, which better boosts performance while preserving power outcome.

Another vital strategy entails customizing the intake and exhaust systems. Updating to high-performance air filters and exhaust headers can minimize back pressure, assisting in much better airflow. This permits the engine to take a breath more freely, bring about boosted burning effectiveness.

Additionally, the implementation of a fantastic read advanced adjusting tools, like dyno screening, supplies exact data that enables targeted adjustments. Frequently keeping track of these efficiency metrics guarantees that adjusting efforts produce the preferred efficiency end results. Collectively, these strategies not only bolster engine efficiency but additionally add to lasting sustainability in engine procedures.

Maintenance for Ideal Performance

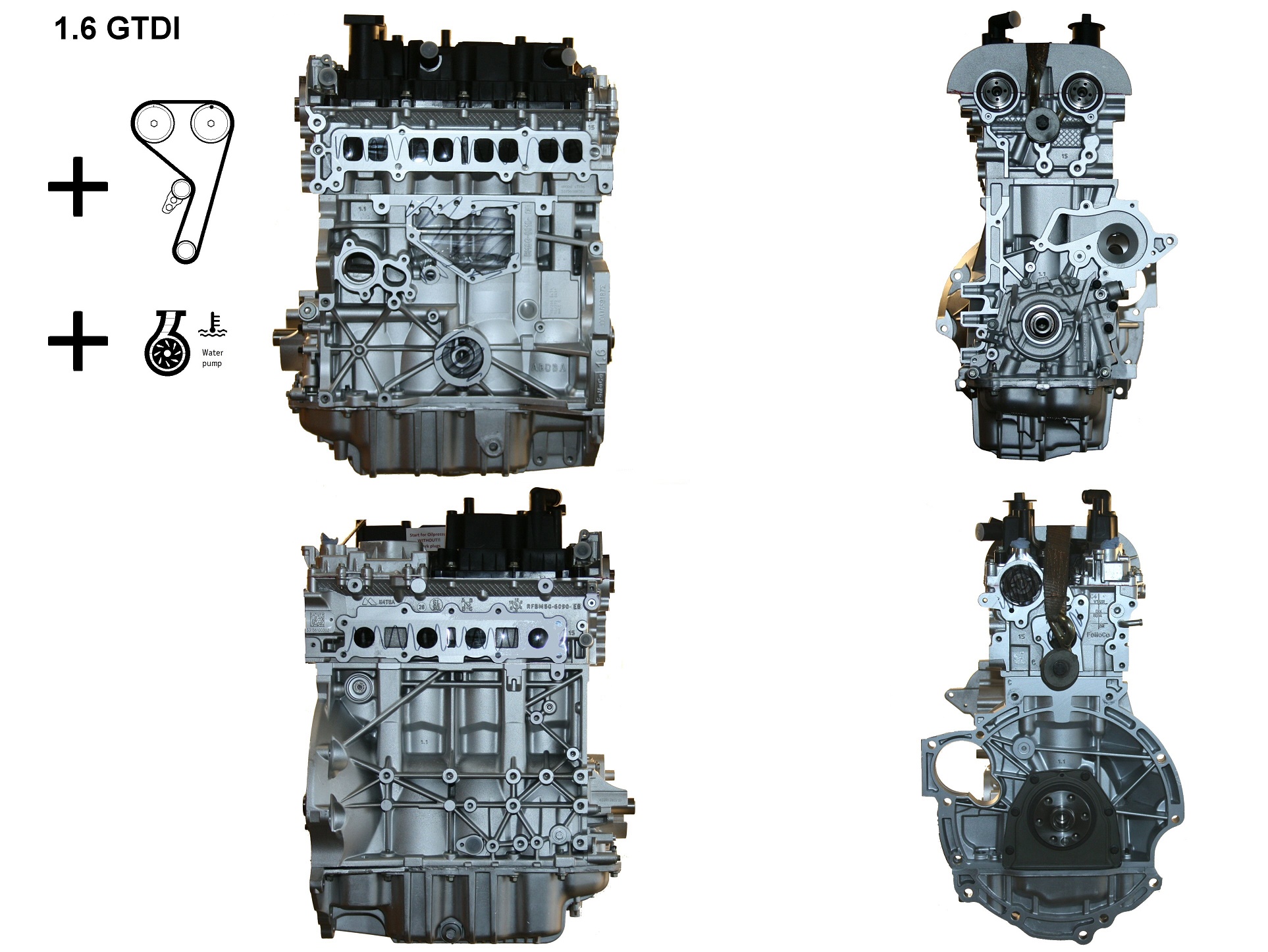

Routine engine maintenance is crucial for accomplishing optimal efficiency and longevity. A well-maintained engine not only runs efficiently yet also minimizes the danger of costly repairs and failures. Trick components calling for regular interest consist of oil, filters, belts, and ignition system.

Altering the engine oil at advised intervals is important, as oil lubes moving parts and protects against overheating. Replacing oil and air filters guarantees that impurities do not harm engine function. Overlooking these parts can bring about decreased performance and potential engine damage.

Furthermore, evaluating and replacing worn belts and pipes is vital to stop unexpected failings. Timing belts, specifically, should be replaced according to the maker's timetable to avoid devastating engine damage.

Ignition system ought to likewise be examined and replaced as needed, since they play a critical duty in ignition and gas performance.

Future Patterns in Engine Technology

Accepting improvements in innovation, the future of engine design is poised to change efficiency and effectiveness across numerous applications. Hybrid and fully electrical powertrains are ending up being significantly traditional, offering reduced exhausts and improved fuel effectiveness.

In addition, technologies in materials science are causing lighter, more powerful components that enhance engine performance while minimizing power consumption. Advanced manufacturing strategies, such as 3D printing, enable the creation of complicated geometries that improve air flow and thermal monitoring, therefore maximizing combustion procedures.

Additionally, the combination of synthetic knowledge and device understanding is readied to change engine diagnostics and efficiency tuning. These innovations can assess large quantities of information in real time, allowing anticipating upkeep and customized performance enhancements.

Verdict

In verdict, opening the power of engines calls for a detailed understanding of great site their technicians and efficiency metrics. Applying reliable adjusting methods and adhering to regular maintenance practices significantly enhance engine capabilities.

Additionally, the engine her comment is here counts on a meticulously adjusted fuel-air mix, ignition system, and cooling system to make certain ideal performance and performance.

Comprehending engine basics likewise involves recognizing the relevance of engine cycles, such as the four-stroke cycle, which includes consumption, exhaust, power, and compression strokes. Proficiency of these fundamental auto mechanics lays the groundwork for checking out more intricate engine dynamics and efficiency metrics, important for maximizing both power output and performance.

Accepting innovations in technology, the future of engine layout is poised to reinvent performance and efficiency across numerous applications.